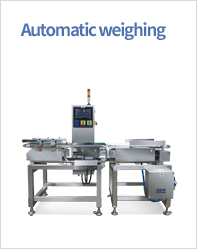

What is an automatic check weigher?

![]()

1. Definition of an automatic check weigher

- Install at the end of a production process and is used to ensure that the weight of a pack of the commodity is within specified limits

![]()

2. Purpose

1) Save raw material cost due to over weight of products

- Manage productivity via weighing data analysis

- Feedback collected data to production line

2) For consumers

- Supplynet weight products via weighing technology

![]()

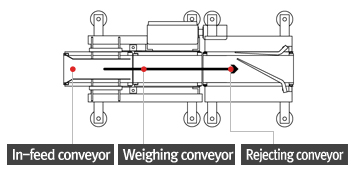

3. Structure

1) In-feed conveyor

- Sub-conveyor for appropriate weighing

- Maintain interval, Anti-shock, Maintain constant speed

2) Weighing conveyor

- Weighing products

- Mounted on a strain-gauge load cell with a motor

3) Rejecting conveyor

- Removing an out-of-tolerance package from conveyor line

Main functions

- By inputting throughput optimal weighing conditions can be automatically set.

- The product length is put in automatically

- Available to control a weighing time and interval according to product conditions

- Discretionary weighing range setting function by absolute and deviation weighing method.

- Auto data back-up when power down or the electrical supply interruption

- Auto Zero tracking function which always set zero value on operation

- Variable speed with inverter

- Temperature stabilization and noise compensation circuits

- Available to control external equipment by input & output interface (barcode scanner, inkjet printer, metal detector, etc.)

- Real time monitoring with a smart phone

- Statistic and print (option)

- External machine compatible (option)

- Integrate with a metal detector (option)

Main features

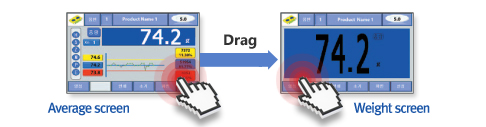

Full color touch screen (10 inch TFT LCD)

Changeable screen type by simply swiping the display

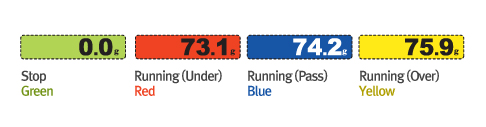

Display color changes according to determination

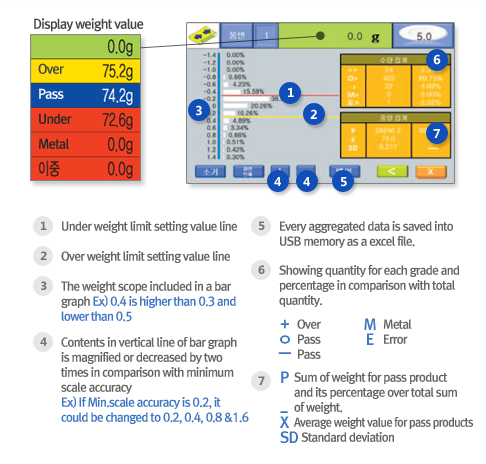

Statistic function and USB backup

Enhanced item list

Weight sorting function by multi rejectors